The fastening condition regular check on the railway section is a time consuming, repetitive and focus demanding process. It is still done by the railway section infrastructure maintainer doing regular inspection walk.

Nowadays, the power of AI algorithms and capability of a modern hardware such as cameras and high-perofmance computers and our unique AI software allow this very important regular process to be automated for each railway infrastructure manager.

- We offer you the reliable robust solution based on AI and optical pattern recognition in two packages:

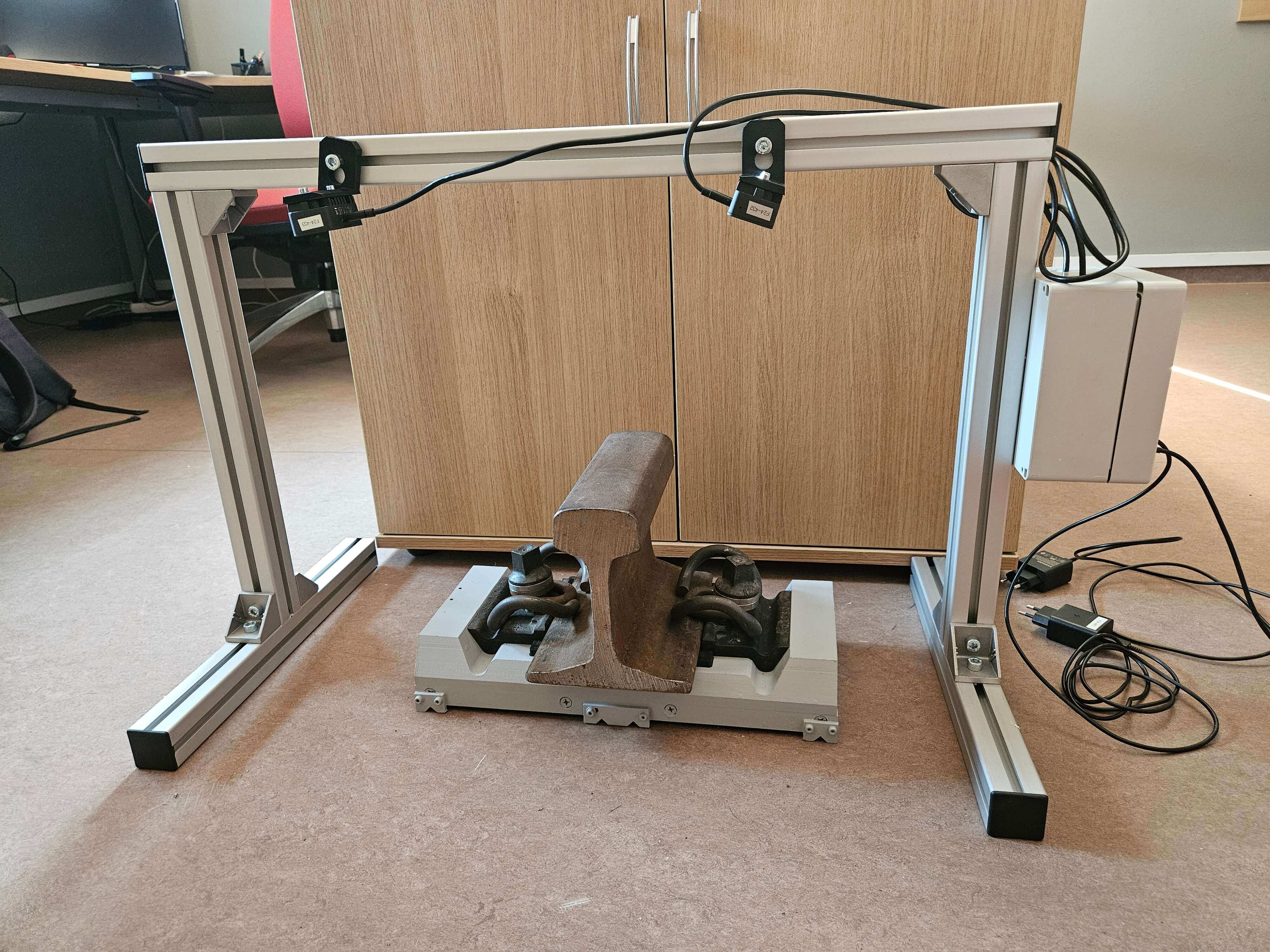

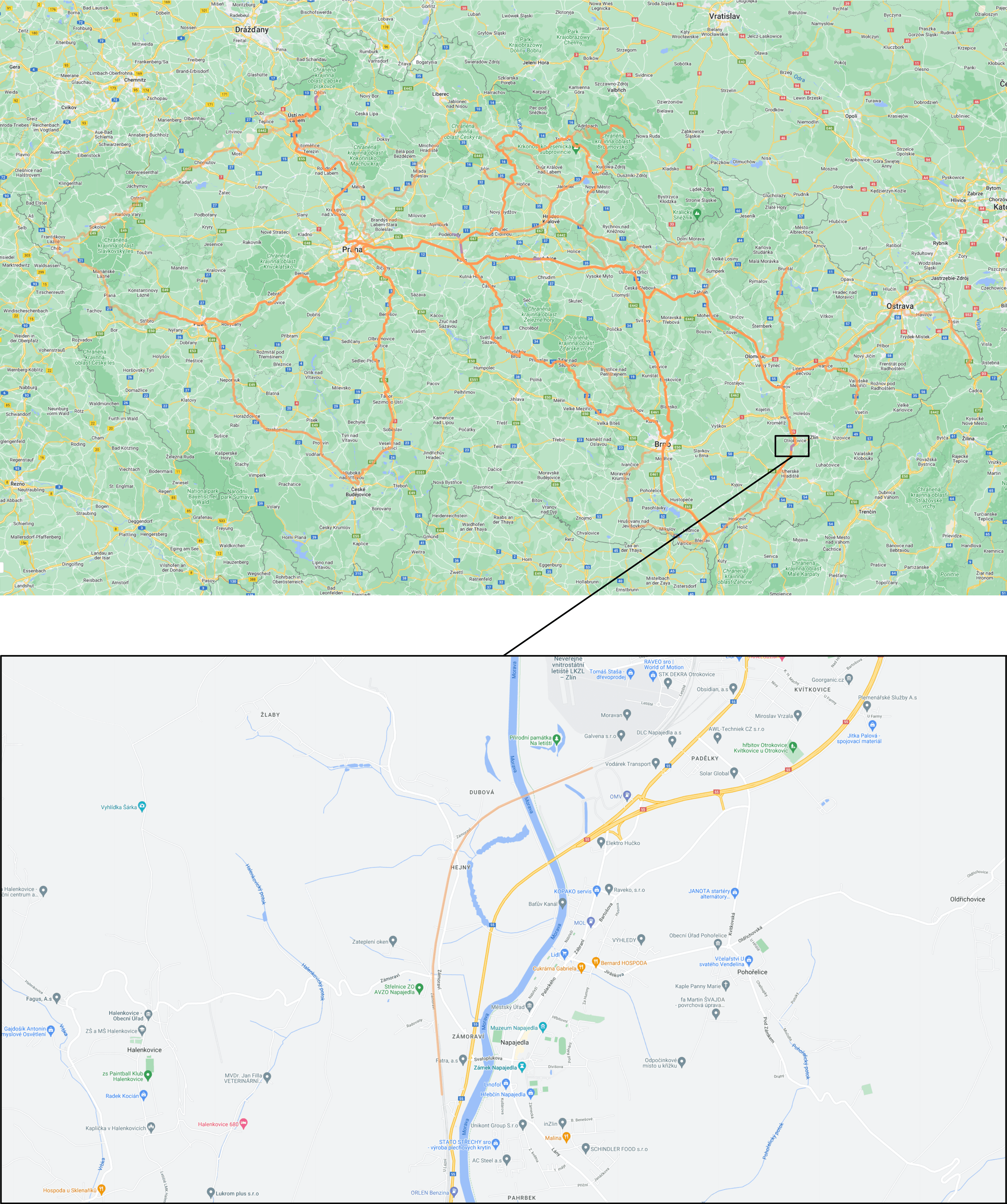

- speed up to 25 km/h :: The smaller solution for railway section maintainers: utilizing matrix camera set for speed up to 25 km/h, mounted on the smaller inspection vehicle, usually with other measurring technologies - geometry, corrugation, rail profile.

- speed up to 250 km/h :: The fully equipped solution for railway network infrastructure managers: utilizing line-scan camera set for speed up to 250 km/h, mounted on the dedicated measuring vehicle, usually with other diagnostics technologies - geometry, corrugation, rail profile, clearance profile, catennary measurement, eddy-current, ultra-sonic defectoscopy.

System Features

- Two hi-res cameras per rail

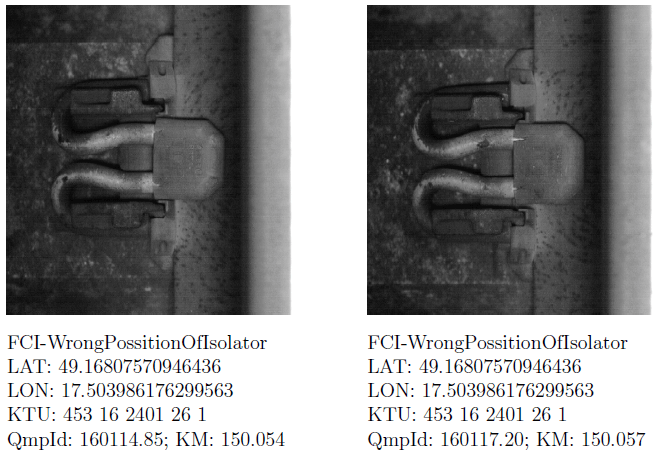

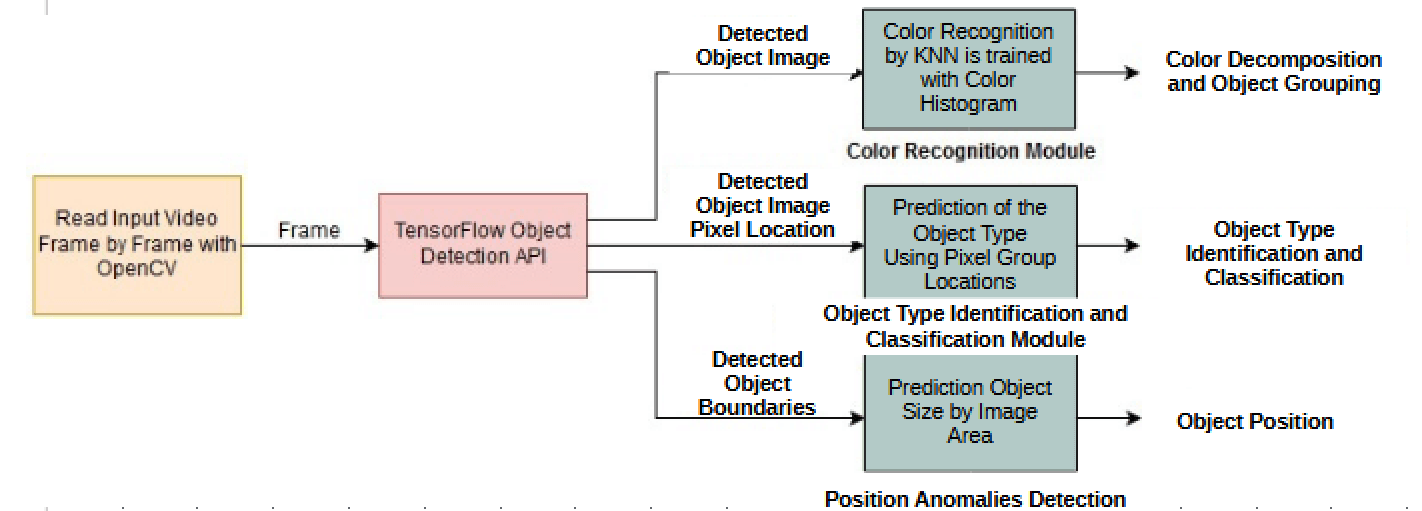

- Real-time object identification

- Defect classification and scoring

- Wide defect type catalogue

- Ready-to-deployment neural network set

- Integration on KZV vehicle with various inspection systems:

- Geometry, corrugation, cleareance profile

- The same measuring vehicle

- One Run -> More Data

Camera Type Options

- Matrix (up to 25 km/h)

- Lines-scan (up to 250 km/h)

Integration Options

- On-board detection

- Defect list export

- Data transfer to a data center

- Data warehouse analytical tool

- Photo, video and map visualisation

- Track section statistics

Fastening Types

Europe: W14, KS24, KS12, K, TR5, FastClip

Asia: Vossloh-300, WJ-8, WJ-7

Support for sustainable development in the EU and the Czech Republic, respecting the priority axes of reducing energy consumption in society.

The solution is environmentally friendly and minimizes electricity consumption.

We contribute to sustainability in energy-intensive transportation and other sectors.

The hardware used is low-consumption. We utilize a small compact camera and single-board computers with low power consumption; other components are also energy-efficient.

For the server, we prefer hardware that allows active power management using ACPI.

The presented system brings savings and efficiency improvements in supervisory and control processes in asset management. Many routine tasks, which require attention, will be performed by machines instead of humans.

Human potential can be redirected to other activities with higher added value.

Operating on mobile devices does not require special vehicle trips and any regular trips can be utilized. For example, the equipment can be installed on any train following its regular route, simultaneously collecting data to capture the condition of the monitored assets and interest objects at that time.

This leads to more efficient use of resources.