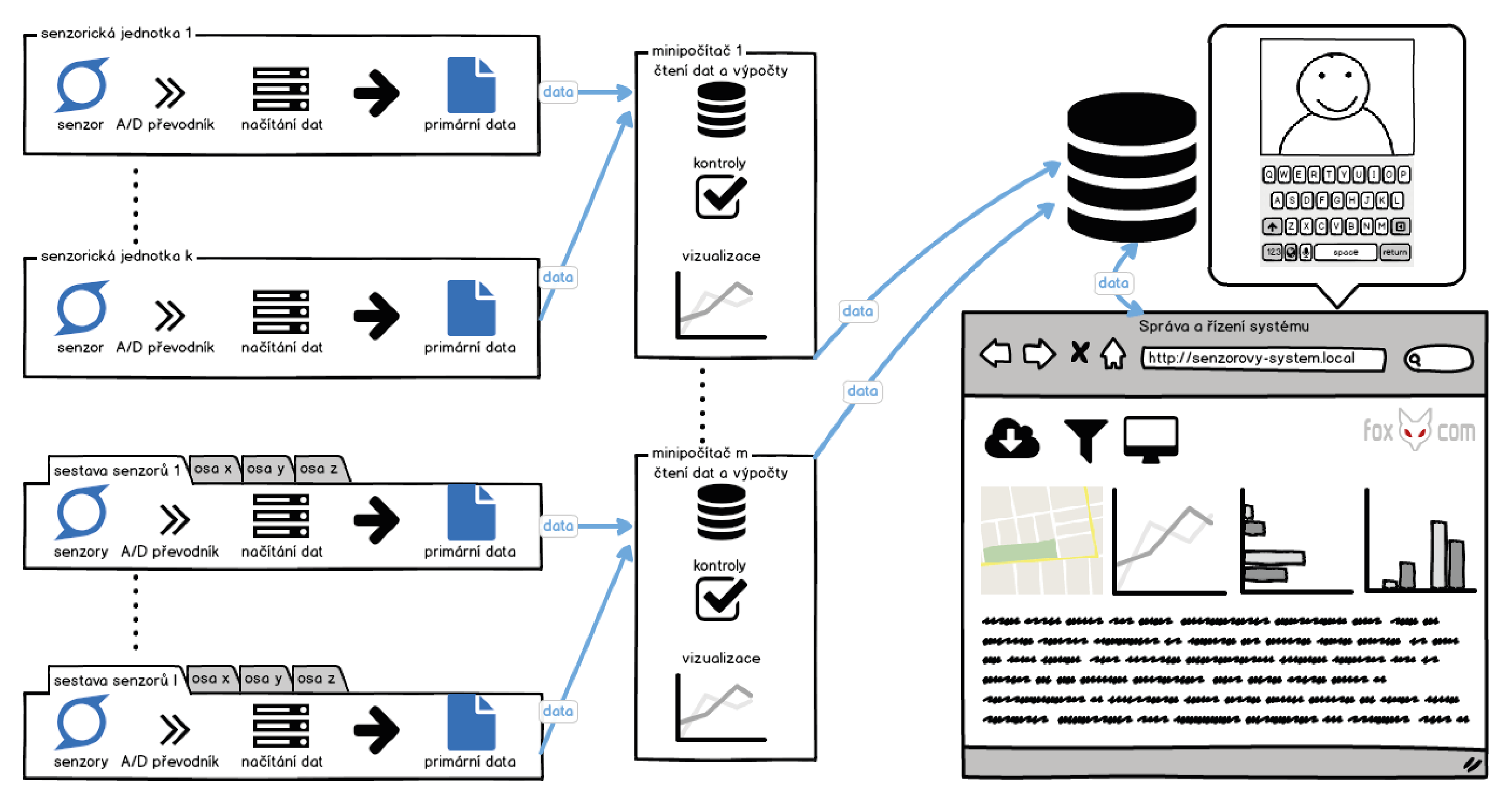

We offer a reliable integrated sensor system for detecting forces acting on objects from the outside. Once installed, the sensors become part of the monitored object. Monitoring occurs fully automatically in a non-stop mode, providing full-time coverage 365/7/24.

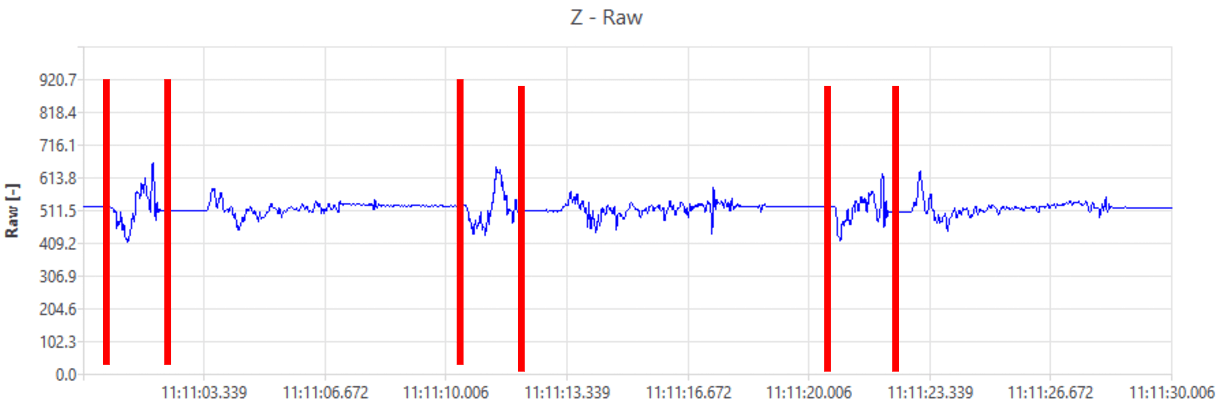

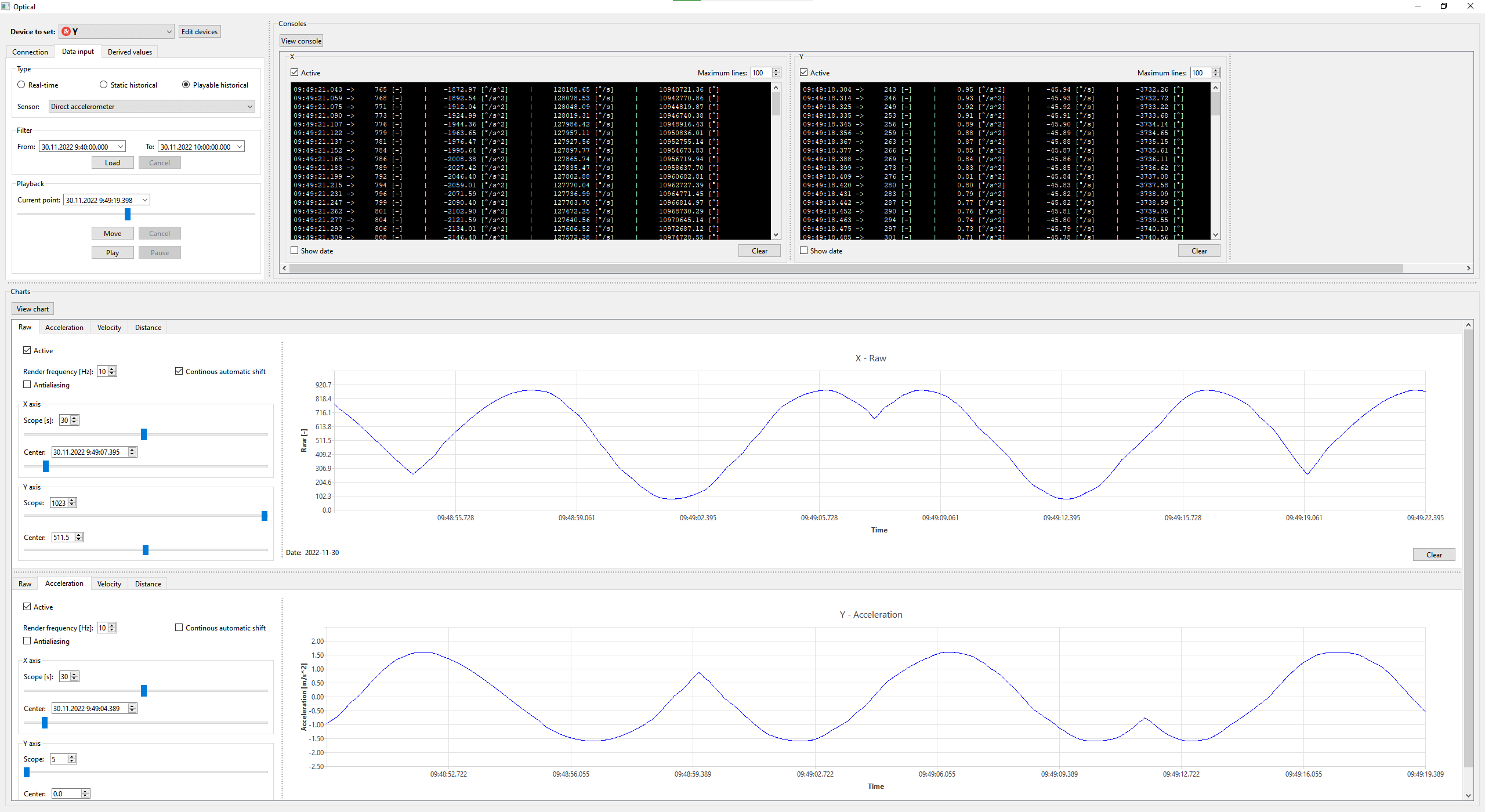

Whether it involves detecting vibrations, oscillations, angle size, and rotation speed, or other derived quantities, everything is monitored and controlled by an intelligent control panel in the software component of the solution.

The set of supplied applications ensures everything from data acquisition from individual measuring devices - IoT sensors, through transmission, to data storage for both online and offline analytics. It also provides a user-friendly interface for controlling the entire system, managing configurations, and connecting to overview dashboards and dispatch and control workplaces.

Features of the detection system

- complete delivery of hardware and software, customized to the needs of the specific project and local client requirements

- the solution operates in non-stop mode, i.e., 24/7/365

- the sensor detects position change

- adjustable sensitivity for detecting fine vibrations as well as sudden shocks or rapid shifts

- the software includes a supervisory control panel, adjustable threshold levels, detection of exceedances, definable events, and alarms

- integration with enterprise ERP, manufacturing systems, monitoring systems, or other types of data warehouses and databases

- also includes a data warehouse, monitoring tool, analytics tool, event viewer, visualization in graphs, and on a map

Physical installation features in boxes

- adjustable sensitivity for each sensor, including correlation of multiple sensors in a single assembly

- patented mechanism for installing boxes in target locations, including cable terminations (design used by companies such as Airbus)

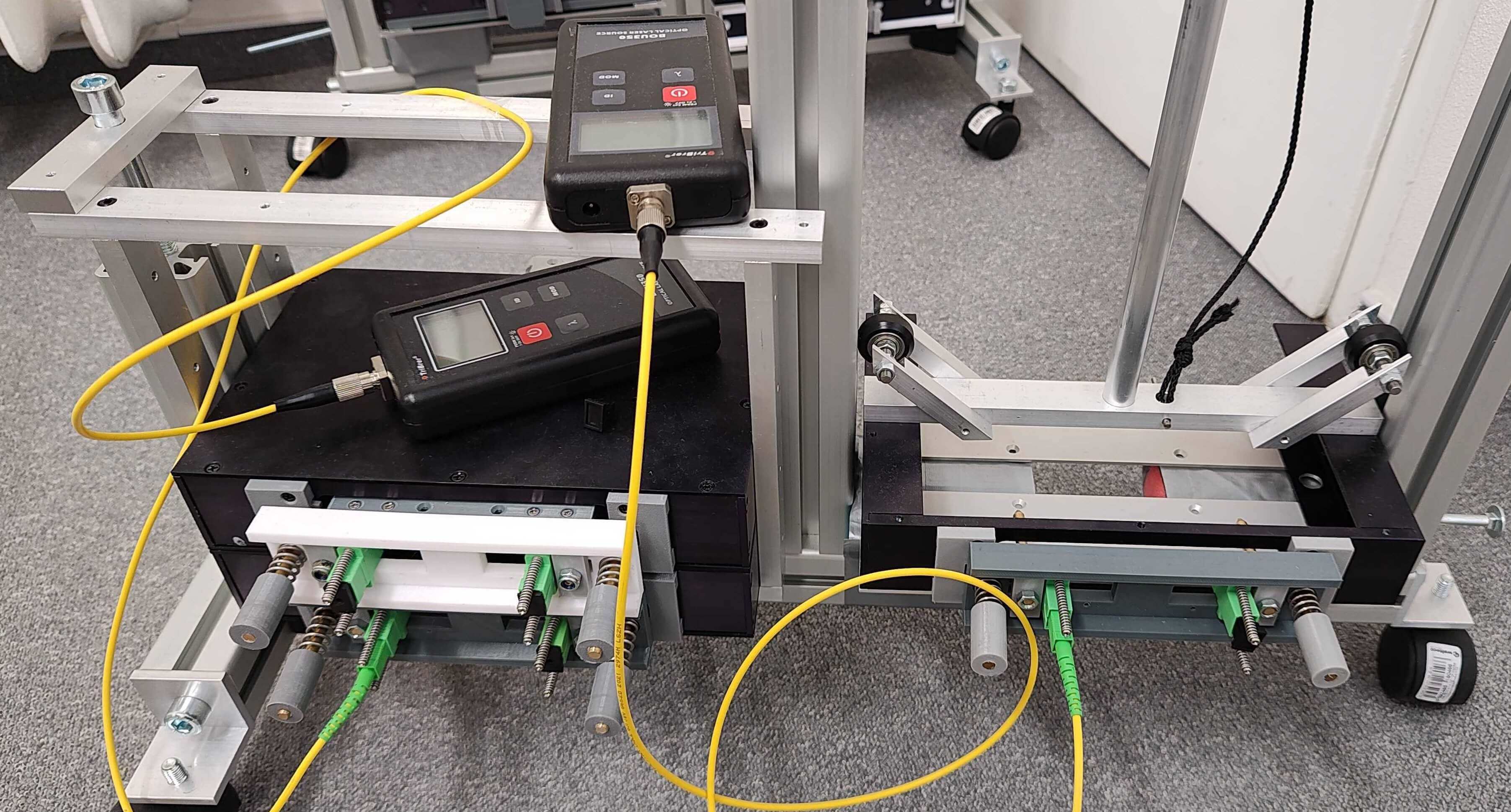

- integrated laser source

- sensor is based on fiber optics

The system's use is practical in many areas

Which one is yours?

rail transportation and rail infrastructure

Detection of vibrations, shocks, and stress on structures or equipment of static or mobile nature in rail infrastructure and rail transportation.

- engines of driving vehicles

- bogies of rail vehicles

- detection of vibrations, oscillations, shifts, or shocks on the rail track (detection of flat spots on rail vehicles, even those not visible to the naked eye)

air transportation and logistics at airports

- detection of impacts when approaching the boarding tunnel/stairs to the aircraft doors

- detection of impacts from boarding platforms and ramp when approaching cargo holds of the aircraft

- detection of impacts during handling of transport containers (ULD - Unit Load Devices) in air transportation during loading and unloading of aircraft and handling in airport and warehouse areas

construction, building structures, buildings

- monitoring of building stability and forces acting on buildings over time

- use in enclosed manufacturing facilities for autonomous control of transport platforms for moving products

- detection of movement and material stress in construction (on bridge and tunnel structures)

transportation

- detection of acceleration and derived quantities in mass transit to meet safety regulations (public transport vehicles - cars, buses, trolleybuses, ships, trams, metro, escalators, elevators)

- monitoring of safety parameters of amusement rides (roller coasters, centrifuges, motion simulators, and other moving devices used in the entertainment industry)

materials engineering

- monitoring of material stress on both stationary and moving objects, such as stress on bridge structures, stress on platforms for transporting and handling heavy loads, etc.

industry

- detection of vibrations on equipment such as turbines, industrial mills, crushers, belt conveyors, and power and industrial boilers

- detection and prevention of issues caused by resonant frequencies

geophysics and geology

- detection of seismic activity

Support for sustainable development in the EU and the Czech Republic, respecting the priority axes of reducing energy consumption in society.

The solution is environmentally friendly and minimizes electricity consumption.

We contribute

to sustainability in energy-intensive transportation and other sectors.

The hardware used is low-consumption. We utilize a small compact camera and single-board computers with low power consumption; other components are also energy-efficient.

For the server, we prefer hardware that allows active power management using ACPI.

The presented system brings savings and efficiency improvements in supervisory and control

processes in asset management. Many routine tasks, which require attention, will be performed

by machines instead of humans.

Human potential can be redirected to other activities

with higher added value.

Operating on mobile devices does not require special vehicle trips and any regular trips can be utilized. For example, the equipment can be installed on any train following its regular route, simultaneously collecting data to capture the condition of the monitored assets and interest objects at that time.

This leads to more efficient use of resources.